November 9, 2015

Batching Best Practices

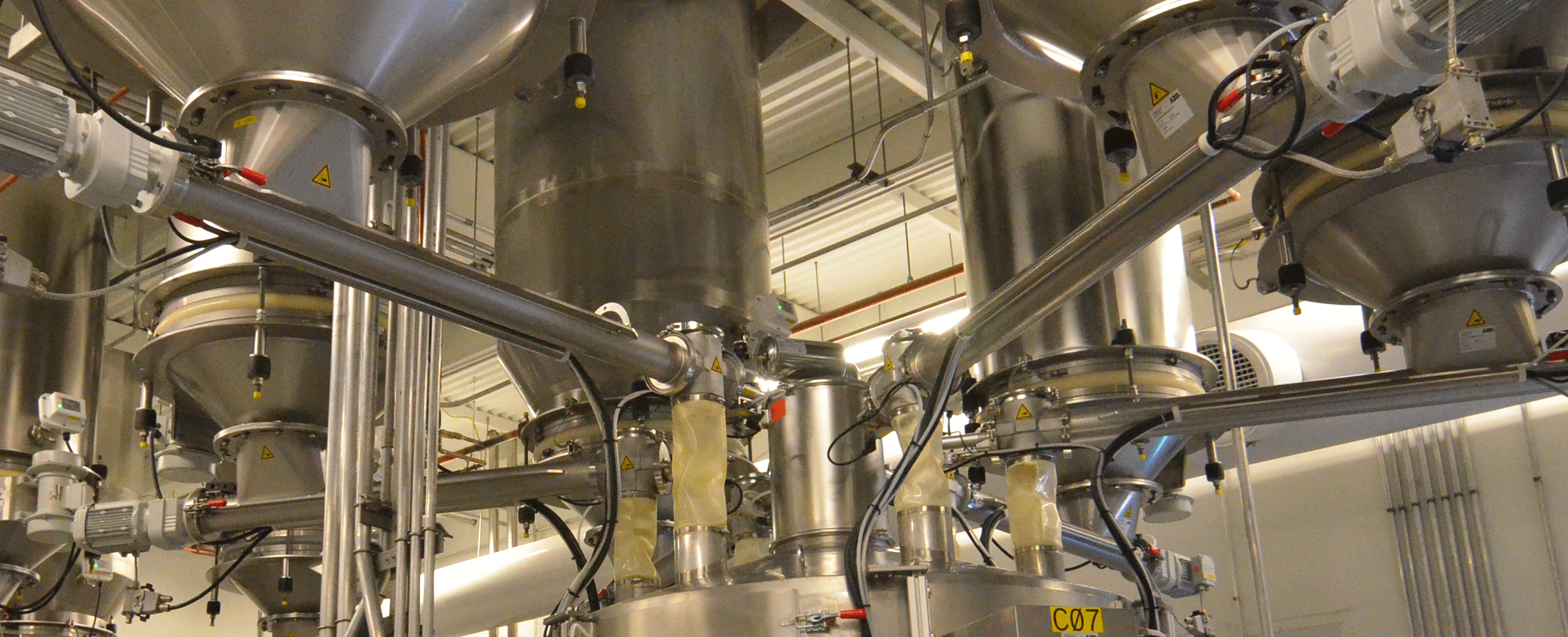

Batching Best Practices INTRODUCTIONThis intent of this paper is to present a few Best Practices I have discovered over the years that lead to an improved performance of ingredient automation (batching) systems. LOAD CELL INSTALLATION Site Preparation All mounting surfaces for the base and loading…