April 21, 2021

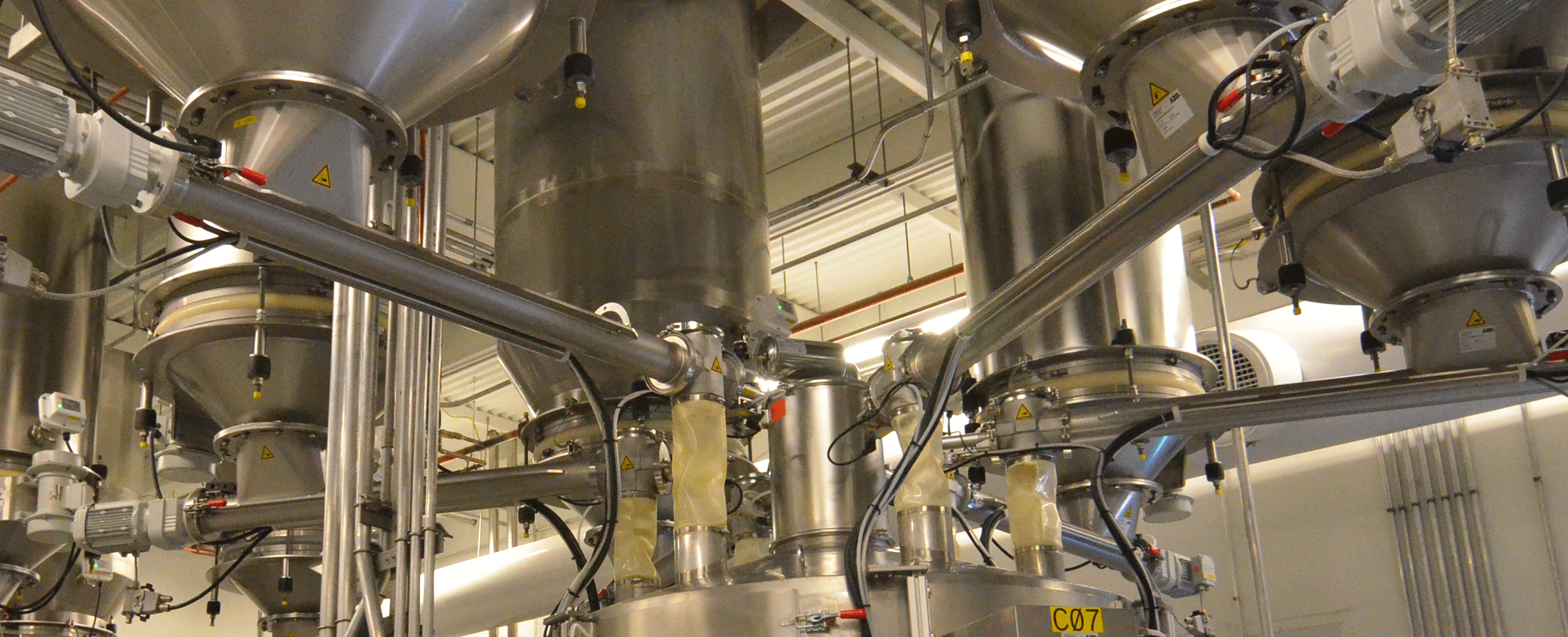

6 Reasons to Automate your Batch Production

While automating batch production is more demanding than automating continuous processes, it can also be tremendously beneficial to your productivity and your bottom line. If you’re considering automating your current batch production processes, here are the six reasons you should do so now. REDUCED…